Online Support Available

For more information or a quotation, please feel free to contact us anytime.

About HWHG

Hongwang adheres to the mission of "devote to green intelligent manufacturing, continue to create value for customers", the vision of "dreams for all", and promotes the core value of "reliable, pragmatic, open-minded, innovative" and the spirit of "innovation, devotion, live earnestly, work happily". We have a trustworthy and highly efficient management team with professional personnel, providing the necessary strength to satisfy customers with excellent products and quality service.

Factory Tour

Development

2005

Hongwang established the first private wide plate cold rolled plant in China.

2008

MAR The first phase of Zhaoqing Hongwang Metal Industrial Co.,Ltd, put into production.

2010

AUG Guangdong Hongwang Investment Group Co., Ltd. was set up to start collectivized operation management.

2011

MAR Sichuan Hongwang Stainless Steel Co., Ltd. put into production.

2012

JULY Henan Hongwang Metal Material Co., Ltd. put into production.

Zhaoqing Hongwang started to build the first 1450mm five-stand tandem mill with continuous annealing and pickling line in China.

2014

JULY Fujian Hongwang initiated the construction project of cold rolled stainless steel. Annual output: 1,000,000 tons.

2015

MAY Shandong Hongwang started the construction project of 1.2 million tons Nickle-based composite materials.

2017

DEC The second phase of Fujian Hongwang put into production. 1700mm five-stand tandem mill with continuous cold annealing and pickling line. Annual output: 600,000 tons.

2018

NOV The first phase of Yangjiang Hongwang started construction. 1450mm hot and cold annealing and pickling line with inline four-stand tandem mill. Annual output: 700,000 tons.

2019

JUNE The project of color-coated coil put into trial production in Zhaoqing Hongwang.

2020

JULY Doctoral workstation of Guangdong Province established in Zhaoqing Hongwang.

AUG The 1450mm 20-high rolling mill and bright annealing line put into trial production in Zhaoqing Hongwang.

SEP Hongwang Group is ranked 485th in the list of the 2020 China Top 500 Enterprises; 231st in the Top 500 Manufacturing Enterprises.

DEC Shandong Hongwang began trial production of surface finishing coil. Annual output: 150,000 tons.

2021

AUG The second phase of Yangjiang Hongwang put into trial production.

Project of stainless steel hot rolled pickling white coil and sheet; annual output: 500,000 tons.

Project of cold rolled stainless steel sheet; annual output: 300,000 tons.

SEP Hongwang Group is ranked 451st in the list of the 2021 China Top 500 Enterprises; 220th in the Top 500 Manufacturing Enterprises.

DEC Hunan Hongwang construction project initiated. Annual output of oriented and non-oriented Electrical Steel: 960,000 tons.

2022

MAY The construction of Hongwang headquarters building officially initiated.

APR The expansion project of cold rolled stainless steel in Fujian Hongwang initiated.

Annual output: 1,300,000 tons.

SEP Hongwang Group is ranked 435th in the list of the 2022 China Top 500 Enterprises; 219th in the list of the Top 500 Manufacturing Enterprises.

2023

MAR High permeability grain oriented and medium to high grade non-oriented electrical steel put into production in Hunan Hongwang.

Online Support Available

For more information or a quotation, please feel free to contact us anytime.

Talented Personnel

Talent is the greatest asset. Hongwang always adheres to the principle of being people-oriented, respecting talent, valuing talent, and cultivating talent. We are committed to building a fair, open, and inclusive development platform, where talent is recognized based on ability and potential. Our aim is to create a talented team with a strong innovative spirit and the courage to take on challenges. Hongwang also strives to create a good environment where everyone can achieve their potential anddisplay their talents.

Chairman's Message

Chairman's New Year Message - 2024 Hongwang Holding Group

As we bid farewell to the past year and embrace the new one, I wish to express, on behalf of Hongwang Holding Group, my sincere appreciation to all esteemed leaders, valued partners, dear friends, and our entire Hongwang family. The year 2024 holds exciting possibilities, and our confidence in advancing is stronger than ever. Wishing everyone a fantastic New Year filled with success and joy!

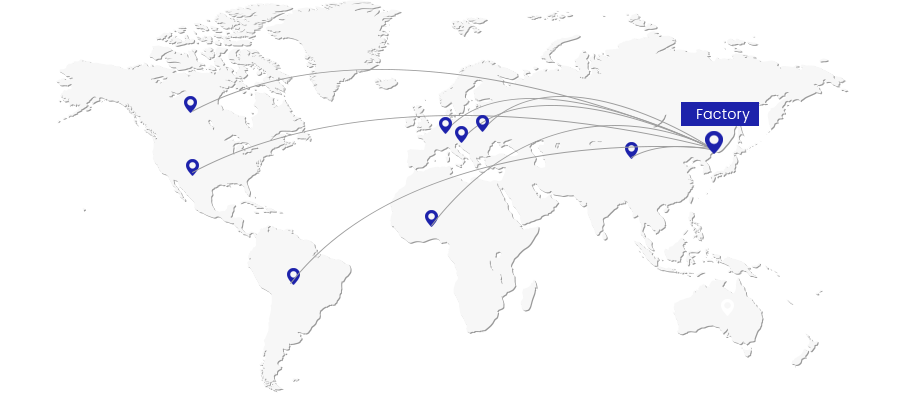

Business Around the

WORLD

Ranked 442th

In the list of the 2024 China Top 500 Enterprises

Ranked 228st

In the list of the Top 500 Manufacturing Enterprises

Ranked 223th

In the list of the 2024 China Top 500 Private Enterprises

Ranked 155th

In the list of the Top 500 Private Manufacturing Enterprises

11+

Exporting Country

8+

Factories Support